SprutCAM is CAD/CAM software with a streamlined workflow and comprehensive functionality. Compatible with any CNC machine: 3/4 and 5 axis milling machine, Lathe, Turning center, Swiss Lathe, Multitasking, EDM. The tool path calculation is performed taking into account the complete machine kinematics and limitations, including collision avoidance and control of axis limits.

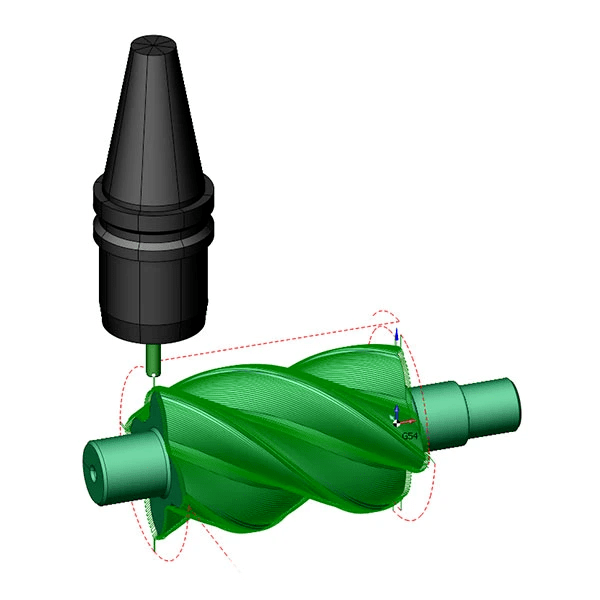

Rotary milling programming

Milling with 4th axis. Production of augers, blades, sprockets, balusters and snails.

- 4-axis indexed machining

- 4-axis continuous machining

- Collision control

- Time saving

4-axis machining

SprutCAM has roughing strategies for quick removal and finishing of materials with the quality required for surfaces in continuous 4-axis machining.

All 3-axis toolpath strategies are available for 4-axis indexed machining.

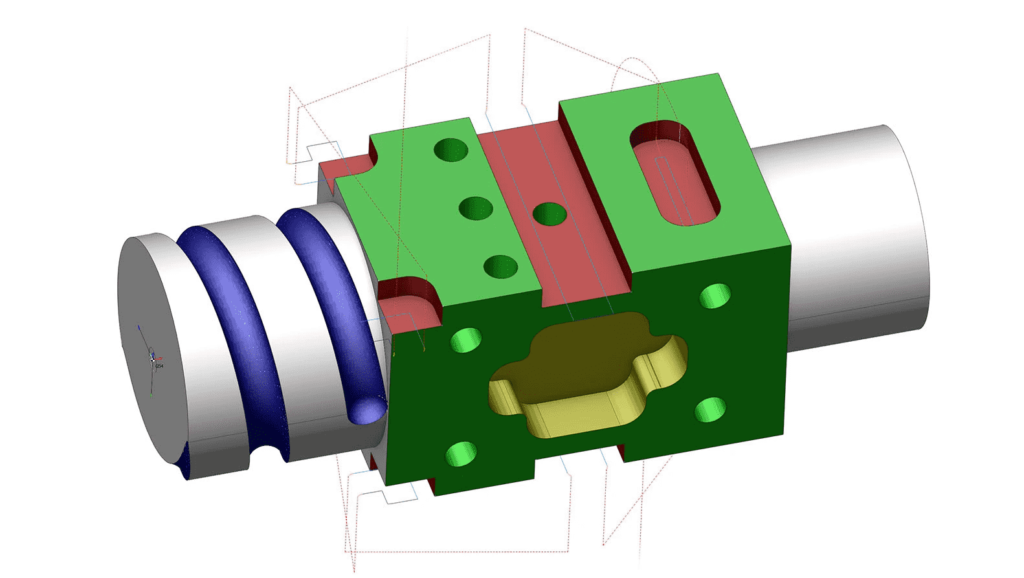

Collision control during toolpath calculation

SprutCAM takes the actual kinematic limitations of the machine into account for the initial toolpath calculation. There is no need for post-processing and separate simulation for collision control and axis limits.

- Tool holder collision control

- Collision control of moving components

- Axis limit control

Machining time savings

Remachining removes material that a previous tool or operation could not remove. In SprutCAM, areas with remaining material are automatically detected.

- Save time with automatic “select same diameter” feature for hole machining

- Save time with automatic flat face detection

- Collision control

- 5D contour operation

- Time saving

Set of strategies for 4 axes

Special strategies for rotary machining.

- Rotary roughing

- Rotary finishing

- Profile machining (5D contour)

All 3-axis strategies are suitable for rotary machining

All 3-axis operations in SprutCAM are suitable for machines with a 4th axis.