Learn more about what's new in SprutCAM Download version 15 and discover how to expand your production. The available tools can provide gains in various aspects of your industry, making them essential for companies seeking the best in their products.cam software expand production

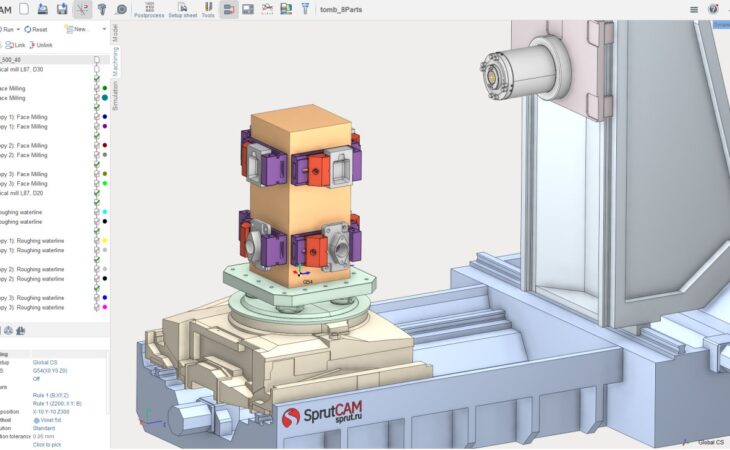

Added the ability to machine multiple parts in a project. The part is defined in the project as a special group of operations. All operations within the group work on a single part. Each part can be placed separately and can have its own origin. Added a special mode for reordering the machining sequence to minimize tool changes.

Added the ability to make a copy of the part. The part copy contains copies of the prototype part's operations. It is now possible to output machined copies based on subroutine calls.

The setup stage is the special group of operations for machining the placed part(s). If you need to manually re-clamp the part, you need to create another setup stage. A new setup stage contains all the same parts as the previous stage. All parts can be tumbled or clamped in a different location, but the initial part of these parts is considered the result of the machining of the previous step.

These parts have completely changed the way multi-tasking machines (MTMs), sub-spindle turning centers, and Swiss-type lathes are designed. These types of machine tools typically have two or more flutes. Two copies of the same part are machined simultaneously. One copy is clamped on the main spindle, and the other is placed on the sub-spindle. The new workflow for programming these machines is demonstrated in the video below.

Create parametric 3D models using sketch, extrusion, and revolution. Use them as parts or fixtures.

The new utility allows you to create robot schematics with additional axes.

In addition to the traditional postprocessor generator (which produces *.sppx files), the ability to develop postprocessors using the most modern and elegant development tools has been added. You can now create a new type of postprocessors—files with the *.dll extension, which are based on the latest version of the .NET platform and use C# as the programming language. Visual Studio Code is offered as the primary development tool. It's incredibly powerful, yet lightweight and free, with Intellisense, tooltip documentation, and all sorts of other features—all of this is now available to postprocessor developers.

The main idea is to combine the familiar concept of a postprocessor generator with the modern object-oriented programming paradigm. This offers advantages such as:

This feature is in alpha and should be used with caution. The public API specification is subject to change. For instructions on how to get started developing new postprocessors, check here.

This feature allows you to add additional equipment to your machine.

The operation is designed to control the gripper tool to move the workpiece within the machine's work area. With multiple parts in total, it allows for the creation of assembly designs. These operations can be used on sub-spindle lathes to move the workpiece from one spindle to another.

New behavior engine and smart hint translation

Smart tips now appear on mouseover.

New Holders Library Window

New Holders window (3D models)

You can add previously prepared support templates from your computer to this window.

The supports previously added in this window are saved in the configuration file and will be loaded automatically.

Axis map for 5-axis machines, precise C-axis handling

It allows you to avoid singularities and collisions by explicitly defining the C-axis value for the tool path. The color on the map shows the minimum possible deviation of the tool normal (when the C-axis value is fixed) from that defined in the job assignment. The normal deviation map panel allows you to define threshold values for these zones. The dotted splines show optimal C-axis trajectories (solutions) when there is no deviation from the original normal, with different values of the "Flip table" parameter and displacement (360 degrees). More information is available in documentation page.

New behavior for part and workpiece primitives

Part and workpiece primitives (parallelepipeds, cylinders, bodies of revolution) are now created in the geometric coordinate system by default. Therefore, when the part is rotated, the primitives now rotate with it. The figure below shows the behavior in previous versions (left) and in version 15 (right).

Added verification support function in rotary roughing operation

This option can be used to avoid collisions between the part and the workpiece. The part isn't static; it updates dynamically while the toolpath calculation takes the upper layers into account. It's perfect for milling sculptures.

Milling tool shank dimensions added

Three new parameters have been added for the basic milling tool types: shoulder length (SHL), shank diameter (SHD), and shank taper angle (STA).

Barrel saw support added

Three new tool types have been added to the Shaped tool group: Barrel Mill, Tapered Barrel Mill, and Lens Mill.

Added offset pass step for coating

This attribute allows you to define the distance between offset passes. "Offset Pass Pitch" is only available when "Offset Pass Count" is greater than 1.

There are three values:

“Power” for 5D coating operation

This option allows you to change the extruder speed depending on the layer height.

Added puncture distance for plasma operation

This distance allows the tool to be retracted to the required distance for punching. There are two values:

New feed types

Replaced Engage and Plunge feed with the Approach feed in several operations.

5D Contour now generates up to 6D toolpaths

The 5d contouring operation is adapted to the 6d toolpath. The operation has changed the "links/leads" tab.

New Feed Control Feature for 5D Contouring

This function allows you to control the feed rate within a limited range for 5D Contour operation.

Adaptive lathe operation

More than twice as fast as traditional lathe grooving. This is achieved thanks to the high working speed and optimized tool path. It uses a tool tip. Read the details here.

Starting point for face milling operation

New CLData command properties window

In the window, you can see the parameters related to the selected command. You can also edit these parameters (you must turn off "Read-only" mode).

Updated command set for manual addition

Updated CAD add-ons

| Software CAD | Version |

|---|---|

| Alibre Design | Up to V22 SP2 |

| Inventor | Until 2021 |

| IronCAD | Until 2021 SP1 |

| Kompas 3D | Up to 19.0 |

| SolidEdge | Until 2021 |

| SOLIDWORKS | Until 2021 SP2 |

| ZW3D | Until 2021 |

Updated integrated importers:

| Domestic importer | Version |

|---|---|

| Parasolid (XTReader) | Up to 33 |

| SOLIDWORKS (SWReader) | Until SOLIDWORKS 2021 |

New interpreters for G-code-based simulation and verification:

New G-code based lathe operation

For use with a turning tool in G-code-based operation, a new operation, "G-code-based turning," has been added. This operation is located in the list. The G-code-based turning operation only supports turning tools. Otherwise, it is similar to the "G-code-based milling operation."

G-code based operation improvements

Commands not recognized by the interpreter can be added to the toolpath as INSERT command text for later use in the postprocessor, for example, to control additional equipment such as lasers, additional machine axes, or coolant.

Arbitrary compensation value for tool radius

Added the ability to disable or set an arbitrary tool radius offset value.

A pop-up tooltip displaying command descriptions, machine processing time, and a complete list of errors for the current block's toolpath

After a short delay of the mouse pointer over the line with the NC program text, a popup tooltip shows a description of the associated nodes of the path tree (CLData commands).

Context menu for working with text

The main actions for working with text are now also available in the context menu, which can be accessed by right-clicking in the text editor area of the parameters panel for G-code-based operations.

New version of ModuleWorks

The new ModuleWorks kernel 5X version 12.2020 has been integrated