SprutCAM is CAD/CAM software with a streamlined workflow and comprehensive functionality. Compatible with any CNC machine: 3/4- and 5-axis milling machines, lathes, turning centers, Swiss lathes, multitasking machines, and EDMs. Tool path calculations take into account the machine's complete kinematics and limitations, including collision avoidance and axis limit control.

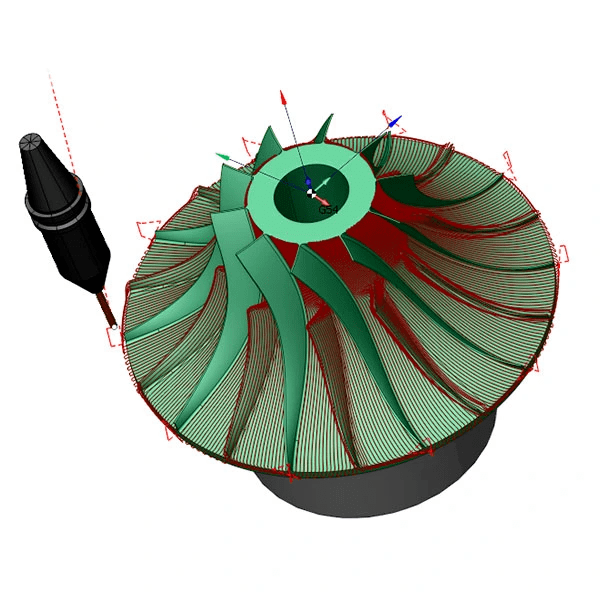

Multi-axis

Indexed milling (3 + 2) and 5 simultaneous axes: for turbines, blades, portals.

- Handling of remaining material

- Strategy calculation

- Collision control

- Kinematic consideration of the machine

- Improve your production process

Inclined Work Plane (TWP)

- G68.2 / CYCLE800 / Space plane

- Automatic and manual local SC transformation for 3+2 machining

Tool Central Point Management (TCPM)

- G43.4 / TRAORI / M128

- TCPM mode for 5-axis simultaneous machining

5-axis programming workflow

SprutCAM always keeps the part updated within the sequence of operations to optimize the strategy and avoid empty cuts.

Every subsequent operation detects the part in the state it was left in by the previous operation.

Collision control during tool path calculation

SprutCAM takes into account the machine's actual kinematic limitations for the initial toolpath calculation. There's no need for post-processing and separate simulation for collision control and axis limits.

- Tool holder collision control

- Collision control of moving components

- Axis limit control

Strategies for tool path control

- Parallel to the horizontal plane

- Parallel to the vertical plane

- Parallel to the 3D plane

- Parallel to the curve

- Through the curve

- Combination between two curves

- Combination between two faces

- Around the rotary axis

Strategies for tool axis control

- Normal to the surface

- Flank

- Fixed

- To the rotary axis

- Through the point

- Through the curve

- Perpendicular to the trajectory

Special 5-axis solutions

- Blade machining

- Machining of multiple blades

- 5-axis portal machining