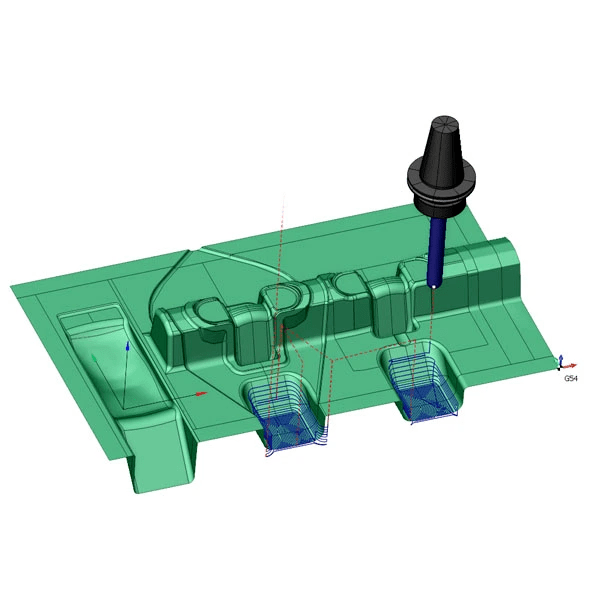

SprutCAM is CAD/CAM software with a streamlined workflow and comprehensive functionality. Compatible with any CNC machine: 3/4- and 5-axis milling machines, lathes, turning centers, Swiss lathes, multitasking machines, and EDMs. Tool path calculations take into account the machine's complete kinematics and limitations, including collision avoidance and axis limit control.

2.5 and 3-axis milling

Production of parts, molds and dies and any other parts on a 3-axis milling machine.

- Remove material quickly

- Get the required surface quality

- Collision control

- 2.5D contouring operation

- Time saving

Sprutcam 14

The new 2.5D contouring operation

A new 2.5D contouring operation has been added, based on the same principle as the familiar 2D contouring operation. Its main difference is that a single operation allows you to machine multiple curves or vertical walls at different heights simultaneously.

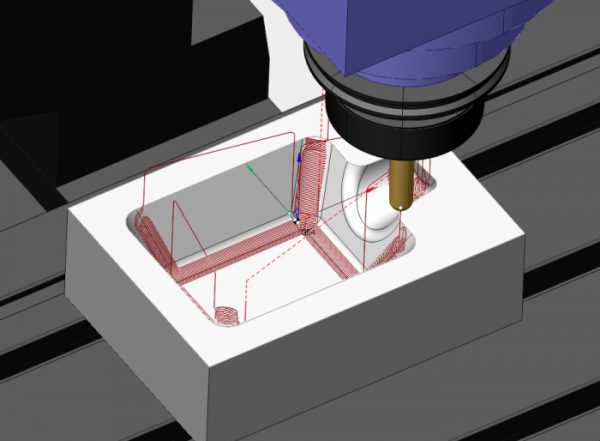

Collision control during tool path calculation

SprutCAM takes into account the machine's actual kinematic limitations for the initial toolpath calculation. There's no need for post-processing and separate simulation for collision control and axis limits.

- Tool holder collision control

- Collision control of moving components

- Axis limit control

Saving machining time

Remachining removes material that a previous tool or operation could not remove. In SprutCAM, areas with remaining material are automatically detected.

- Save time with the automatic “select same diameter” feature for hole machining

- Save time with automatic flat face detection

- Collision control

- 5D contouring operation

- Time saving

Set of 3-axis trajectories

A new 2.5D contouring operation has been added, based on the same principle as the familiar 2D contouring operation. Its main difference is that a single operation allows you to machine multiple curves or vertical walls at different heights simultaneously.

- Waterline roughing

- Drilling operation

- 2D contour

Sketch-based machining

Design a part in the included 2D CAD and use it directly for machining.