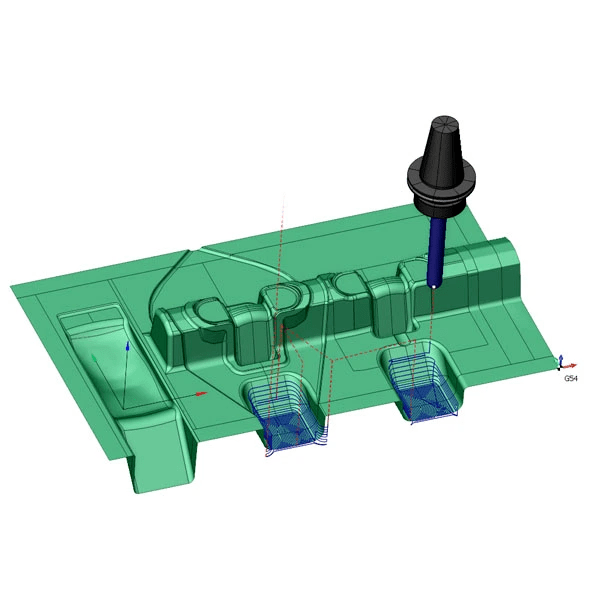

SprutCAM is a CAD/CAM software with an optimized workflow and full functionality. Compatible with any CNC machine: 3/4 and 5-wheel milling machine, Lathe, Turning Center, Suizo Lathe, Multitasking, EDM. The calculation of the tool tray is carried out taking into account the kinematics and complete limitations of the machine, including collision prevention and control of the ejes' limits.

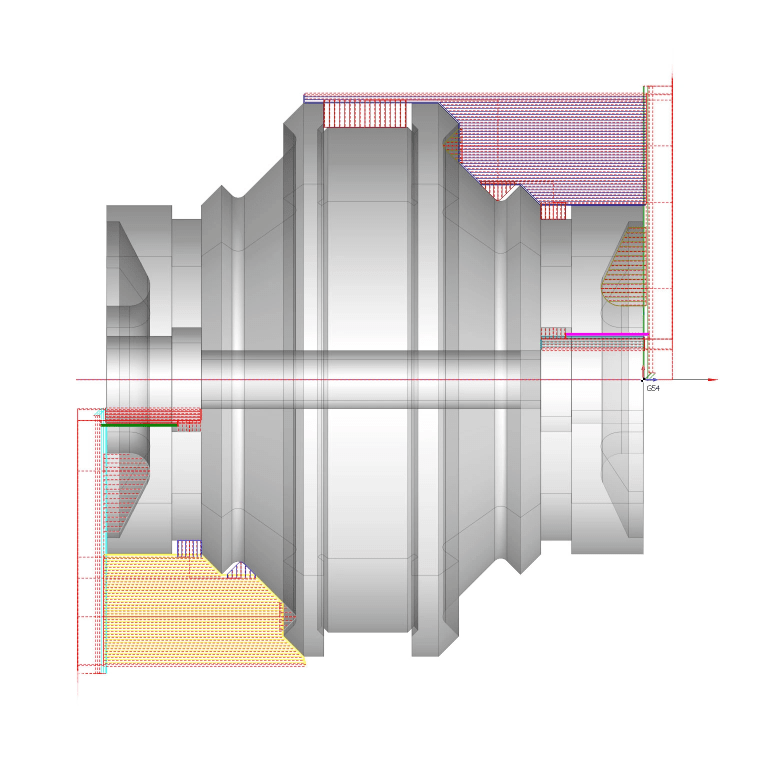

CNC lathe programming

Turning and boring of cylindrical, conical and profiled surfaces, threaded, cutting, counterpointing, cutting and boring of needles.

- Remove the material quickly

- Get the surface quality you need

- Collision control

- 2.5D contour operation

- Aservrar tiempo

Functions to Deliver on SprutCAM

All types of turning operations

- Facing

- ID and OD roughing

- Refinement

- Enhebrar

- Frontal groove and groove

- Turning sharpener machining

- Cutting pieces

Fixed turning cycles

Depending on user preference, SprutCAM can optionally generate G code using lathe cycles.

Simplified CNC programming workflow

SprutCAM calculates lathe tool trays and all other mechanized processes using the native kinematics of the CNC machine. This means that collisions between machine wheels and working parts are managed automatically to calculate the tool tray.

CNC programming becomes visual, the work flow is simplified

- Save time viewing tool trays

- Interactive approximation definition

- Drag and drop contour editing

- Subprocess database

Advanced turning programming

- Supports shaft B (5th shaft)

- Turning parts of any profile