SprutCAM is a CAD/CAM software with an optimized workflow and full functionality. Compatible with any CNC machine: 3/4 and 5-wheel milling machine, Lathe, Turning Center, Suizo Lathe, Multitasking, EDM. The calculation of the tool tray is carried out taking into account the kinematics and complete limitations of the machine, including collision prevention and control of the ejes' limits.

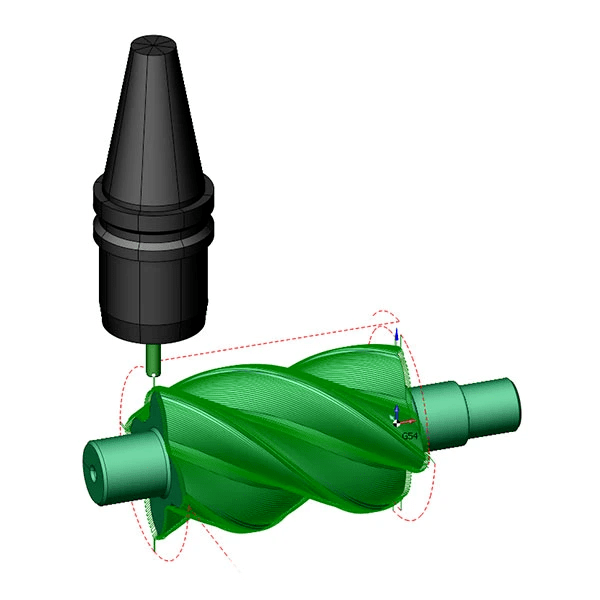

Rotary milling programming

Milled with 4th ejector. Production of bars, blades, pins, balustrades and caracoles.

- 4-axis indexed mechanized

- Continuous mechanized with 4 shafts

- Collision control

- Aservrar tiempo

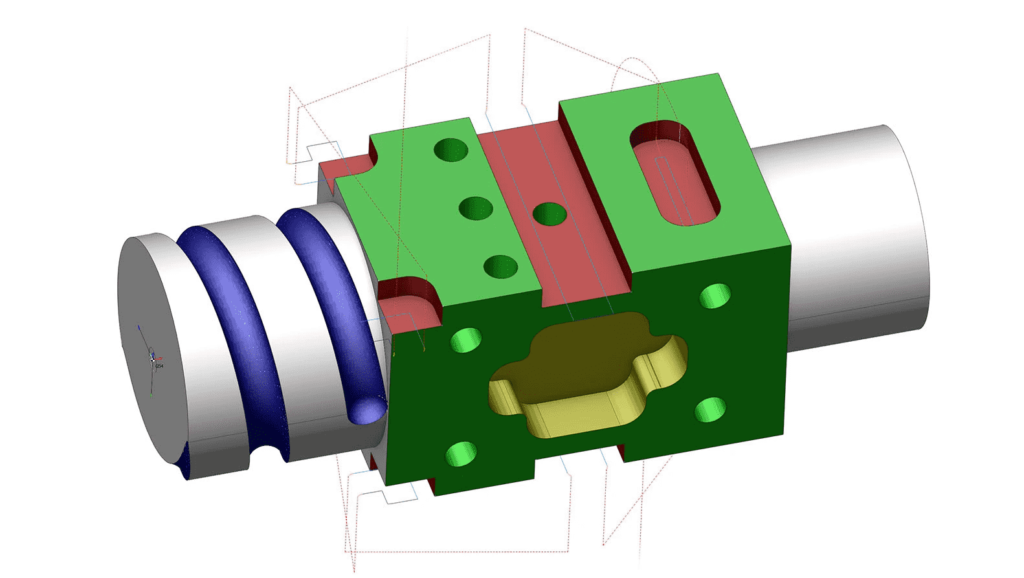

4-axle mechanized

SprutCAM has roughing strategies for rapid elimination and finishing of materials with the quality required for the surface using continuous 4-wheel machining.

All 3-eje tool trayectory strategies are available for the 4-eje indexed mechanized.

Collision control during tray calculation

SprutCAM takes into account the real kinematic limitations of the machine for the initial calculation of the tray. There is no need for separate postprocessing and simulation for collision control and ejection limits.

- Tool holder collision control

- Collision control of mobile components

- Axle limit control

Mechanized time saving

The remechanized process eliminates material that a previous operation could not eliminate. In SprutCAM, areas with remaining material are automatically detected.

- Save time with the automatic function "select the same diameter" for the hole machining

- Save time with automatic detection of flat faces

- Collision control

- 5D contour operation

- Aservrar tiempo

Set of strategies for 4 wheels

Special strategies for rotary mechanization.

- Rotary grinding

- Rotary finish

- Profile machining (5D contour)

All 3-axle strategies are suitable for rotary mechanization

All 3-axle operations on SprutCAM are suitable for machines with a four-axle.