Computer numerical control (CNC) is a system that allows machine control, primarily used in lathes and machining centers. It allows simultaneous control of multiple axes through a list of movements written in a specific code (G-code). For this reason, NC (Numeric Control) was developed in the 1940s by the Massachusetts Institute of Technology (MIT), initially using punched tapes. With the advent of the computer, it evolved into CNC. This achieved the goal of manufacturing complex, serial, and highly precise parts, especially when used in conjunction with current CAD/CAM programs.

The introduction of CNC into industry has radically changed industrial processes. Highly complex profiles are easily machined. 3D structures become relatively easy to produce, and the number of process steps requiring operator intervention is drastically reduced. CNC has also reduced the number of human errors (which increases product quality by reducing rework and waste), streamlining assembly lines, and making them more flexible, as the same assembly line can now be adapted to produce another product in a much shorter time compared to traditional production processes. Keeping pace with technological developments in information technology and the trend toward increasing user interactivity, machine code and language have also evolved.

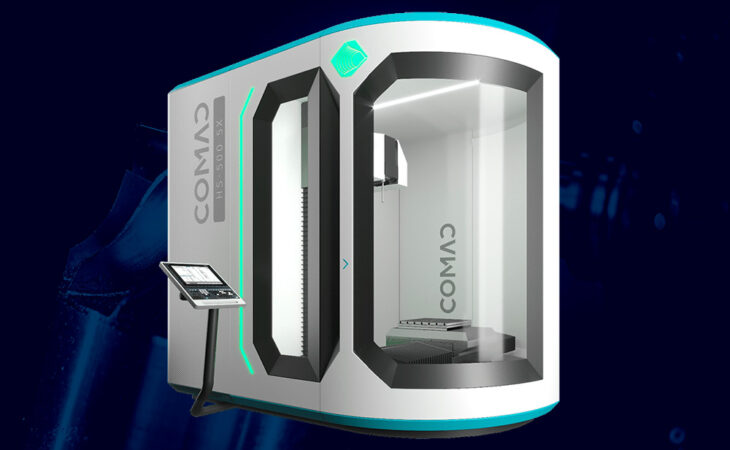

The type of machine you use CNC varies depending on your work process.

Source: https://ccvindustrial.com.br/o-que-e-cnc/

Learn more about COMAC CNC machines here.